Manufacturing of catalytic devices by 3D-printing

|

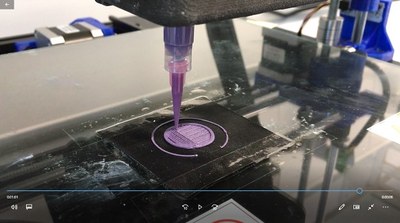

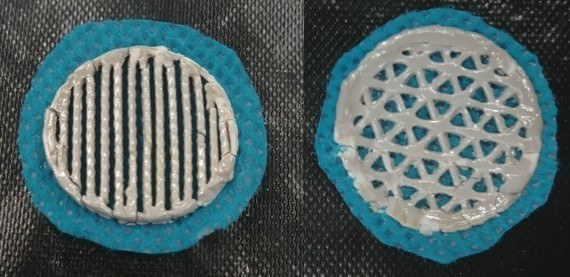

Three-dimensional (3D) printing by robocasting is an additive manufacturing technique in which the desired material is extruded and sequentially deposited in layers to form a three-dimensional object. The advantages of this fabrication method are the high flexibility of materials and shapes, the precise control of the features of the printed object and the low cost of the set-up. Nowadays, 3D printing is considered a powerful technology for the fabrication of structures used in a high number of different applications. We use binder-free 3D printing to fabricate catalytic devices and use them in different processes, like ammonia decomposition over Ni/CeO2 to obtain hydrogen for fuel cell applications and photocatalytic processes over Au/TiO2.

|

|

|

|

Some relevant publications:

Lucentini, I., Serrano, I., Soler, L., Divins, N.J., Llorca, J. Ammonia decomposition over 3D-printed CeO2 structures loaded with Ni. Applied Catalysis A: General, 2020, 591, 117382.

Elkoro, A., Soler, L., Llorca, J., Casanova, I. 3D printed microstructured Au/TiO2 catalyst for hydrogen photoproduction. Applied Materials Today, 2019, 16, 265-272.

Share: