Catalytic membrane reactors

|

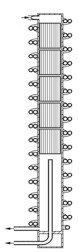

The use of catalytic membrane reactors, with simultaneous generation and separation of hydrogen, appears as an attractive approach to optimize downstream separation and to substantially simplify on-site/on-demand fuel reformers. Catalytic membrane reactors reduce capital costs by combining the reforming process and hydrogen separation in one system, allow an enhancement of the fuel conversion of the equilibrium-limited processes, and are able to directly produce a high purity hydrogen stream for feeding PEM fuel cells if dense Pd-based membranes are used. We develop fuel reformers equipped with catalytic membrane reactors and model them in order to design control systems as interface between fuel reformers and fuel cells. |

|  |  |  |  |  |

|---|

Some relevant publications:

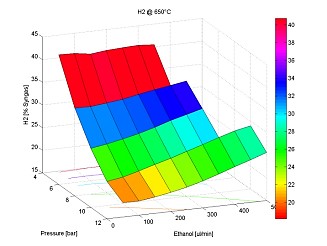

Hedayati, A., Llorca, J. Experimental study of 2-methoxyethanol steam reforming in a membrane reactor for pure hydrogen production. Fuel, 2017, 190, 312-317.

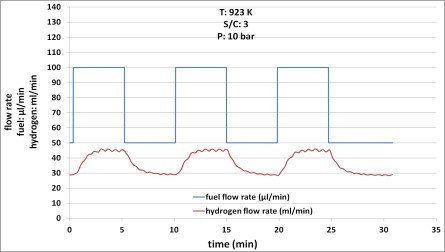

Hedayati, A., Le Corre, O., Lacarrière, B., Llorca, J. Dynamic simulation of pure hydrogen production via ethanol steam reforming in a catalytic membrane reactor. Energy, 2016, 117, 316-324.

Koch, R., López, E., Divins, N.J., Allué, M., Jossen, A., Riera, J., Llorca, J. Ethanol catalytic membrane reformer for direct PEM FC feeding. International Journal of Hydrogen Energy, 2013, 38, 5605-5615.

López, E., Divins, N.J., Llorca, J. Hydrogen production from ethanol over Pd–Rh/CeO2 with a metallic membrane reactor. Catalysis Today, 2012, 193, 145-150.

Share: